+91 98811 44511

ESI - CAE AND PROCESS SIMULATION

Manufacturing Process Simulation cum Validation Solutions

SYSWELD

Welding Assembly process involves Thermal, Mechanical and Metallurgical property changes in parts welded together.

SYSWELD helps accurately predict the residual stresses, distortion, plasticity, hardness, yield strength, cracks, carbon content, fatigue life. bid strength, microstructure and weld quality.

All types of welding processes including Arc (TIG/ MIG), Spot, Laser, Electron Bam, Plasma, Friction Stir can be simulated with SYSWELD.

Simulated results can help users optimize welding input parameters like source heat, angle, velocity, power, number of passes, sequence, clamp locations etc. thus saving the pains of lengthy process of prototyping and achieving best weld joints.

Interested in a demo or want to know more?

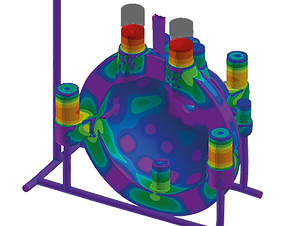

PROCAST/ QUIKCAST

PROCAST and QUIKCAST simulate Casting processes including Sand Casting, Gravity Casting, Continuous Casting, Centrifugal Casting, Pressure Die Casting (LPDC/ HPDC) and Investment Casting.

It helps in accurate prediction of defects like blow holes, porosity, inclusions, pinholes, shrinkages, hotspots, air entrapments, deformation, residual stresses, microstructure, back pressure etc.

It helps users optimize die and process parameters like locations of gates, risers, chills, sleeves, feeders and insultation, die pre-heating, piston control, tilt angle, poring velocity, gas pressure, shell thickness etc. during the entire process of filling and solidification.

Interested in a demo or want to know more?

HEAT TREATMENT

Heat Treatment is a module of SYSWELD which focuses on multi-physics involved in heat treatment processes including quenching, carburizing, nitriding, carbonitriding, tempering, case hardening, induction hardening.

It helps in accurate prediction of hardness, toughness, strength, residual stresses, distortion, carbon content and selection of media, temperature, cooling speed etc.

It helps in identifying effects of PWHT (post welding heat treatment) on overall distortion once welding and heat treatment are carried out sequentially.

Interested in a demo or want to know more?

IC.IDO - VIRTUAL REALITY

IC.IDo is an Industrial Immersive Virtual Reality solution which helps bring your product to life without physically constructing a single thing.

IC.IDo lets you can walk around your product in a true-to-life environment at a 1:1 scale, looking at it, reaching for needed tools, and interact with your new product concepts as you, or your customers, would in real life.

In this way, any unforeseen assembly, operating, and maintenance challenges can be experienced in time to identify them and fix them.

IC.IDo allows Virtual Integration for validation for collision or clash, visibility and accessibility to parts for service or production requirements, including aspects of the human ergonomics.

It can be used effectively in collaboration between design, production, after sales support and training teams.

Interested in a demo or want to know more?

PAM STAMP

Sheet metal forming, stamping, deep drawing, punching, blanking etc. form an important part of fabrication processes.

PAM STAMP includes sheet metal processes like hot forming, hydro forming, tube bending to accurately estimate changes and defects like spring back distortion, splits, surface defects, cracks, wrinkles, residual stresses, thinning, tube ovalization.

It helps users to take measures to improve die and punch life, surface finish such as use of media like gas, pellets, annealing, counter loading etc.

Interested in a demo or want to know more?

PAM COMPOSITE

PAM COMPOSITE offers complete simulation chain to identify and fix manufacturing defects of composites products made of short, long, or continuous fibers.

It accurately and easily determines of geometrical and material properties of “as-built” composite products, aiding design departments early in product development.

It is one tool that covers processes like Draping and Thermoforming, RTM, HPRTM, CRTM, VARI, Curing, Crystallization, Sheet Molding Compound.

It helps in optimizing tool velocity, temperature and pressure cycle, clamping conditions and force, laminate sequence, ply orientations and tooling design.

Interested in a demo or want to know more?

VIRTUAL SEAT

Seating is an important aspect of mobility whether in automobiles, railways, aircrafts or marine transportation. Important design considerations like occupant comfort (static, dynamic, thermal), safety, robustness, space and weight optimization, seat belt design and regulatory requirements make seating simulation very complex.

Features like human whiplash modeling, crash simulation, H-point, posture simulation, airbags and cabin design make Virtual Seat Solution very useful in design of seating systems.

Interested in a demo or want to know more?

INTERIOR SOLUTION

ESI Interior Solution offers a unique capability to virtually test and optimize the cabin layout, while simultaneously improving the car’s range for real driving conditions.

ESI Interior Solution is embedded with human models from different anthropometries and populations for you to choose from. They have been developed specifically for comfort evaluation.

It helps in engineering the thermal equipment of the cabin and seat, assuring optimum passenger comfort and energy consumption for both nominal and in-operation conditions. Engineering teams can test occupant thermal comfort, accounting for heated and ventilated seats, and the overall cabin HVAC system.

Combined with Virtual Seat solution which enables the passenger to change its inclination, it can virtually test passenger available living space, seat static, and dynamic comfort.

Interested in a demo or want to know more?

SIMULATION X

System simulation is created to efficiently model, simulate, and analyze arbitrary machines and plants' behavior. It is used in a multitude of industries and applications such as vehicles, construction & industrial machinery, energy systems, aerospace, medical technology, and consumer devices.

SimulationX, is a platform for modeling, simulating, and analyzing technical systems, including mechanics, hydraulics, pneumatics, electrics, and controls, as well as thermal, magnetic, and further physical behavior.

One, two and three dimensional model libraries with basic elements representing physical phenomena as well as comprehensive component libraries with out-of-the-box application-oriented model elements.

Interested in a demo or want to know more?

CAE & Analysis Solutions

VA ONE - VIBRO ACOUSTIC

VPS - VIRTUAL PERFORMANCE

ACE+ & OPENFOAM CFD

ESI VA One is a single environment for vibro-acoustics analysis and design. It allows engineers to perform accurate predictive noise and vibration design assessments early in the design cycle to meet product performance objectives. Users can meet aggressive design-time constraints, ensuring engineering decisions can be made when they most benefit the demands of a multi-disciplinary development environment.

The successful deployment of vibro-acoustic simulation and the resulting improvements to vehicle acoustics has led to reduced interior noise from sources such as powertrain, tires, and suspension.

For aircraft wind noise vibro-acoustic analysis in combination with CFD data works as an ‘end-to-end’ solution and reduces dependence on expensive wind tunnels.

VA One enables satellite and space hardware designers to confidently design and build their product using high-quality composite materials to meet the optimum performance of the spacecraft through launch, flight, and deployment.

Interested in a demo or want to know more?

ESI's flagship product, ESI Virtual Performance Solution (VPS), gives you the power to know the performance of the product in terms safety, lightweight features, durability, drivability, noise, and vibration without ever requiring real tests or real prototypes with reduced costs and shorter timeframes.

With ESI VPS, virtually evaluate complex new tests for new vehicles:

-

Engineer vehicle structure and batteries, with respect to regulations and precertification

-

Protect passengers in autonomous vehicles with an advanced airbag system

-

Guarantee pedestrian safety with respect to electric vehicles

-

Test the drivability in multiple scenarios, including waterflow management and water crossing

-

Increase durability and reduce interior noise thanks to a smart, lightweight car design that absorbs vibration and noise

-

Design and certify lightweight cars, including battery packs (battery versus structure weight)

Interested in a demo or want to know more?

ACE+ Suite is an advanced CFD and high-fidelity Multiphysics simulation software package supporting the automotive, semiconductor, energy, microfluidics, and biotech industries, amongst others. With ACE+ Suite, engineers can virtually test the performance and behavior of their designs before they are manufactured, for the most extreme innovation requirements.

This tool offers the broadest range of physics disciplines including flow, heat transfer, stress/deformation, chemical kinetics, electrochemistry, biochemistry, electrostatics, electromagnetics, hypersonics, plasma and more – in any combination from a single environment.

ACE+ Suite also includes Design Space Exploration, Optimization and Reduced Order Model modules allowing you to fully understand and fine-tune designs.

Interested in a demo or want to know more?